Elastomer Repair

Problem

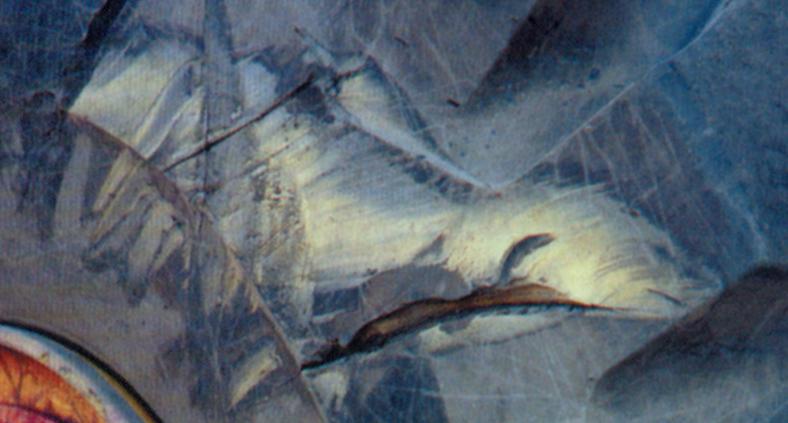

As can be seen from the photograph, the rubber fender of this tugboat owned by the Panama Canal Commission (PCC) had been severely gouged due to contact with other marine vessels.

The PCC approached Thortex to provide an impact and abrasion resistant refurbishment solution.

Application

The areas to be repaired were degreased and any frayed or fragmented rubber cut back to provide a sound repair area. Prior to the application of Flexi-Tech Primer, the rubber was scarified to produce a good profile/key.

Elastomer Repairs were then effected using our 80 Durometer grade, solvent-free flexible repair system Flexi-Tech 80 EG which has outstanding mechanical strength.

Based on the success of this application, the PCC opted to use Thortex elastomeric repair products for the refurbishment of other tugboat rubber fenders.

Problem

Both inside and outside surfaces mostly on sharp edges were severely effected from erosion, abrasion and UV attack. In picture clearly show inside view of wear out sharp edge due to erosion.

Application

Product is rubber coating and application was performed according to the product instruction of use. Rubberized paste grade elastomer being applied to fill cavities and veedout surfaces for restoration oforiginal profile.

Problem

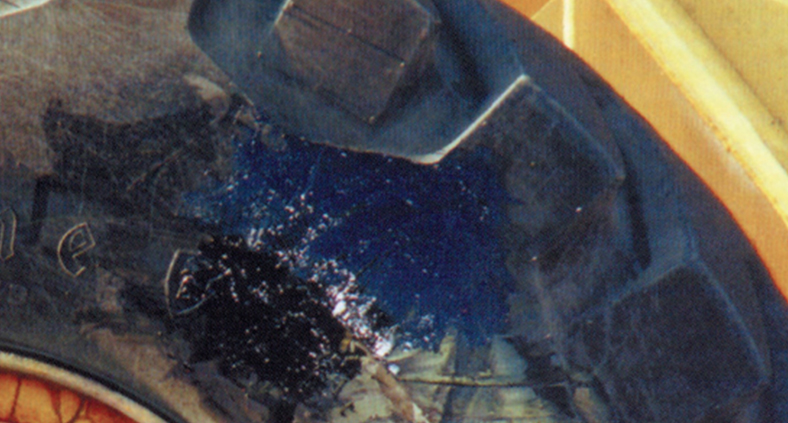

As the close-up photograph shows, this tyre had suffered deep damage due to a heavy impact.

This off road vehicle was used in an industrial facility that was operational twenty four hours a day. Due to the replacement cost for a new tyre and the length of downtime required, thecompany wanted to undertake a high performance repair instead.

Application

The surface was prepared by abrading with a wire wheel and all loose rubber was cut away. The surface was then primed and Flexi-Tech 60 EG was applied to all areas needing repair.

Due to the limited downtime available, heat lamps were used to speed up the curing of the Flexi-Tech Eg. The total time to complete the repair was only six hours, which also gave the customer a massive cost saving.

The customer now uses Flexi-Tech products for all his off road tyre repairs.

Problem

This conveyor belt was used for transporting wood chips from one part of the plywood mill to another.

The conveyor belt had ripped partly due to the sub-zero temperatures which it very often had to operate in and also due to general wear and tear.

Application

A grinder was used to roughen andclean the surface of the belt.

Flexi-Tech 60 RG was used to repair the damaged belt with heat lamps being used to keep the affected areas warm and accelerate the cure of the belt.